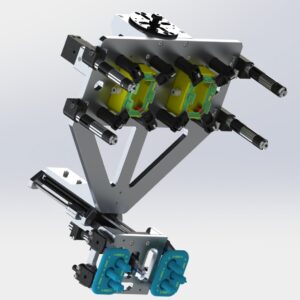

- We produce this special costum End Of Arm Gripper for automotive industry costumer.

- It is so called 2K tool ( mould proces ) , where upper part component is made of (ABS+fiberglass) hard component and in lower bottom sectionwe produce finished part which is overlayed with soft material ( rubber-TPU ) component.

- ( IBM machine injects fiberABS material and TPU at the same time as the mould is closed )

- Cycle goes like this:

- Gripper enters in open mould where we connect and center gripper ( lock with pneumatic mechanism ) with special reference 0,3mm accurance to the mould.

- ejecting pins eject top and bottom parts in one step.

- with upper centring we reference the hard component ( ABS+fiberglas material ) parts and grip them in raster centring special holders.

- In bottom mould we just collect finish product 2K parts ( made of hard component+soft componentl )

- Then gripper hand disconect from centring and we move upper product parts and insert them lower raster in same mould

- To simplify , we transfer upper parts and we put it in lower raster mould that parts can be injected with overlayer of rubber ( TPU ) .

- Onece we do this we exit with gripperhand and we placed finished bottom parts on conveyor outside IBM machine.

Ljubljana, Slovenia, EU

+386 (0)40-733-743

Mon - Fri 08.00 - 16.00

+386 (0)40 733-743

Mon - Fri 08.00 - 16.00

Have a Question?

WE'D LOVE TO HELP.

EOAT EXPERTS d.o.o.

Address: Ulica Ane Ziherlove 10, Ljubljana, SLOVENIJA

Email us at: info@eoatexperts.com

Phone: +386 (0)40-733-743

Our office is open from Monday to Friday 08:00 – 16:00