this is complete automation feeder for 4 inserts to specified raster 2+2 parts in ordfer to collect all insert at once with costume Robot Gripper

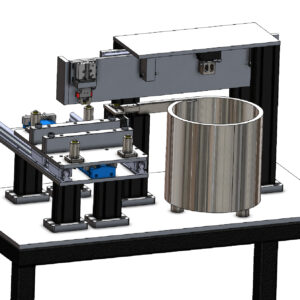

Automated feeder:

With help of our subsuplier who produce us a vibrating unit we programe to doze metal inserts. The concept of pneumatic feeder, isolating one insert and place it to refference pin we construct in our house. In one cycle we pick&place 4 metal inserts out of vibrating dozer and place them on reference pins.

Watch the video!

Feeder has SIEMENS PLC unit with touch screen display which controls the cycle . PLC directs the feeder and in connection with IBM machine robot instructs – gives feedback when parts ( metal inserts ) are on possition to collect with robot gripper hand.

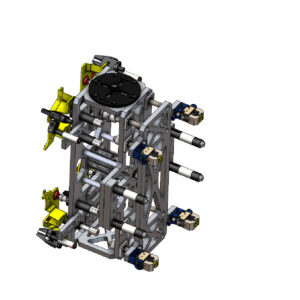

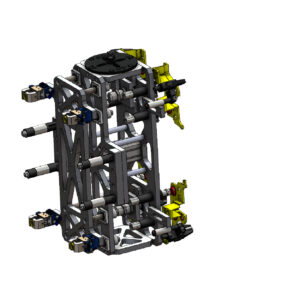

End Of Arm Tooling : gripper gand is made to collect 2 finished parts out of IBM mould machine.

On front side of gripper hand we collect finished parts out of plastic mould, on the other side we hold metal inserts with pneumatic paralel grippers in 0,1mm reference to each other and points according to raster pins in mould to which we place with linear cylinders the inserts on.

To minimaze and to accurate alining the gripper hand with refference to level with IBM tool we use special pneumatic lock fingers.

.